Everything you need to know about our company

We are a leading global manufacturer of customised stainless steel slides

Since 1992, our factory in Döbeln in the heart of Saxony has been producing stainless steel slides that are unrivalled anywhere in the world. Instead of industrial production based on a modular principle, atlantics deliberately favours manual work and only uses high-quality materials such as stainless steel. After all, our aim is no less than to produce unique and particularly durable slides for our customers.

The source of inspiration for our medium-sized, owner-managed company is our own play instinct. With its help, we are constantly creating new and surprising slide designs. Each of our fascinating slides not only impresses with its high practical value and exquisite materials, but also with its elegant design, attention to detail and first-class workmanship.

It is the creative wishes of our customers that spur us on as a slide manufacturer to always find the best solution. And for us, the best solution means harmonising maximum safety, maximum enjoyment, a variety of possible uses and the local conditions of the installation site. No matter how big the challenge or how short the time – with atlantics you can always rely on a smart and accurate slide result.

What sets atlantics slides apart

Manufactory

handcrafted production in manufactory quality

Planning

customised planning according to customer requirements

Quality

particularly durable and sustainable

Design

detail-orientated with unique surface quality

Certification

approved production according to EN 1090

Made in Germany

guaranteed manufactured in Germany

atlantics in numbers

30+

Years of Experience

2.500+

Realised Projects

60+

Countries

Insights

Pictures from the attraction manufactory

From planning to assembly – in our manufactory, many creative minds and professional craftsmen are involved in turning an idea into a unique play experience.

Film about the Company

How a slide attraction is created at atlantics

For the C42 Citroën showroom in Paris, we designed and manufactured an adventure slide with a height of 27 metres and a length of 64 metres. Within a construction period of three months, a mega stainless steel slide was created in our factory that is unrivalled.

Safely stowed away, the slide set off on its 1,000 kilometre journey to the French capital. Here it was installed and polished to a mirror finish by our assembly team. Since then, it has been providing visitors of all ages to the showroom with unique experiences.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationQuality

Our Certifications

Steel structures according to EN 1090

We are certified for welding in steel and metal construction in accordance with manufacturer qualification EN 1090-2. All welding work is carried out by certified welding specialists and a welding expert – for maximum safety of our slides and customised products. In addition, the manufacturer qualification is an important prerequisite for metal construction work in the building inspectorate area and serves as proof of quality assurance in our manufactory for you and us.

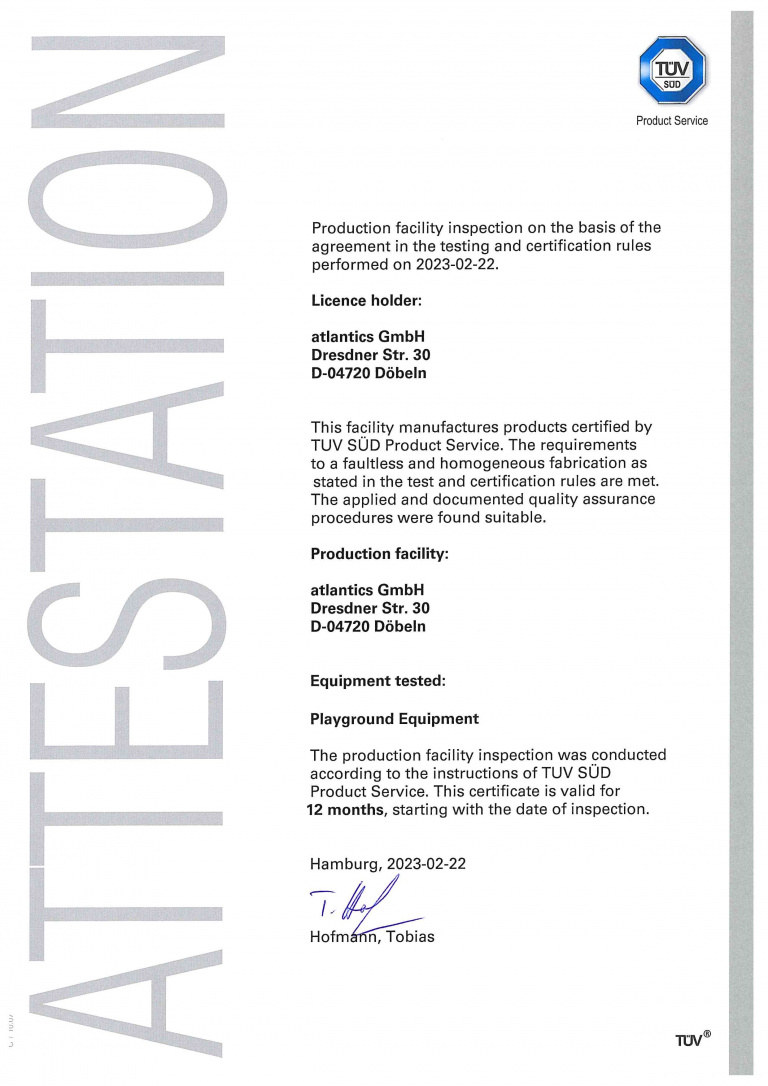

TÜV-certified manufacturing facility

Our manufactory is inspected annually by TÜV Product Service as part of the production site inspection. For you, this not only means an increased level of safety, but also the certainty that all our products are manufactured in accordance with professional and DIN standards. In addition, TÜV Product Service’s certified safety engineers are on hand to advise us on the planning and realisation of our slides and custom-made products.

Jobs

Current Vacancies

Our work is characterised by precision, creativity and the highest quality. We love designing unique slide attractions for our international customers and manufacturing them with dedication in our factory in Döbeln. Become part of our family-run team and help shape our extraordinary play and adventure worlds in the future. We look forward to receiving your application!

Fitter for assembly work in Germany and Europe (m/f/d)

Truck driving licence up to 7.49 t required

Accommodation is in hotels and guesthouses in single rooms

Additional catering expenses are paid according to legal regulations

Full-time 40h/week, assembly tours mainly Mon-Fri

Metal worker / Construction mechanic (m/f/d) with professional experience

TIG welding pass desirable but not mandatory

Full-time 40h/week, working hours Mon-Fri 7:00 – 15:45

Have we piqued your interest?

Then please send your detailed application documents, preferably in PDF format, by e-mail to: job@atlantics.de.