About Us

Everything important

about Atlantics

“The source of inspiration for our medium-sized and owner-managed company is our own play instinct.”

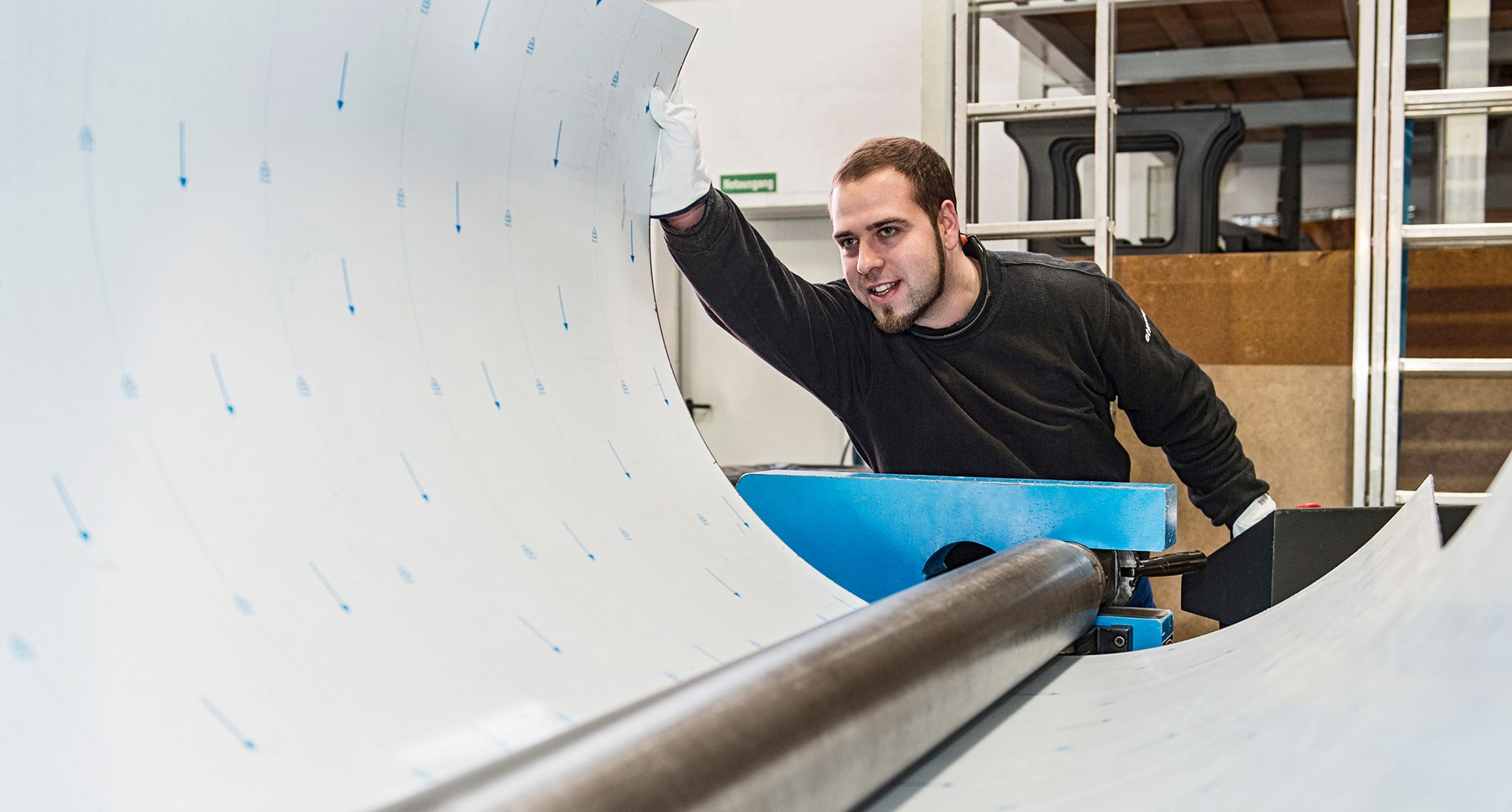

Since 1992, our factory in Döbeln, in the heart of Saxony, has been producing stainless steel slides that are unparalleled in the world. Instead of industrial production based on a modular principle, we at atlantics consciously rely on manual work and process exclusively high-quality materials such as stainless steel. Because our aim is nothing less than to produce unique and particularly durable slides for our customers.

The source of inspiration for our medium-sized and owner-managed company is our own play instinct. With its help, we are constantly creating new and surprising slide shapes. Each of our fascinating stainless steel slides impresses not only with its high utility value and exquisite materials, but also with its elegant design, attention to detail and first-class workmanship.

It is the creative wishes of our customers that spur us on as a slide manufacturer to always find the best solution. And for us, the best solution means perfectly harmonizing maximum safety, maximum enjoyment, a variety of possible uses and the local conditions of the installation site. No matter how big the challenge or how tight the time may be – at atlantics you can always rely on a smart and accurate slide result.

That's what

sets us apart

Handicraft production in manufactory quality.

Individual planning according to customer requirements.

Production according to EN 1090 – tested and certified.

Particularly durable and sustainable quality.

Guaranteed manufactured in Germany.

Production process

of a stainless steel slide

A look

behind

the scenes

For the C42 Citroën showroom in Paris, we designed and manufactured an adventure slide with a height of 27 meters and a length of 64 meters. Within three months of construction, a mega stainless steel slide was created in our factory that is second to none. Safely stowed away, the slide began its 1,000-kilometer journey to the French capital. Here it was installed by our assembly team and polished to a high gloss.

Our

certificates

Steel structures

according to EN 1090

We are certified according to EN 1090-2 for welding in steel and metal construction. All welding work is carried out by certified welding specialists and a welding engineer – for maximum safety of our stainless steel slides and custom-made products. In addition, the manufacturer qualification is an important prerequisite for metal construction work in the building supervisory area and serves you and us as proof of quality assurance in our factory.

TÜV-tested

production facility

Our factory is monitored annually by TÜV Product Service as part of the factory inspection. For you, this means not only an increased level of safety, but also the certainty of professional and DIN-compliant production of all our products. In addition, the tested safety engineers of TÜV Product Service are available to us as consultants in the planning and implementation of our slides and custom-made products.